Send us a sketch or drawing of your application requirements. We’ll make a sensor configuration drawing for your review. Email sensors@philtec.com

Send us a sketch or drawing of your application requirements. We’ll make a sensor configuration drawing for your review. Email sensors@philtec.com

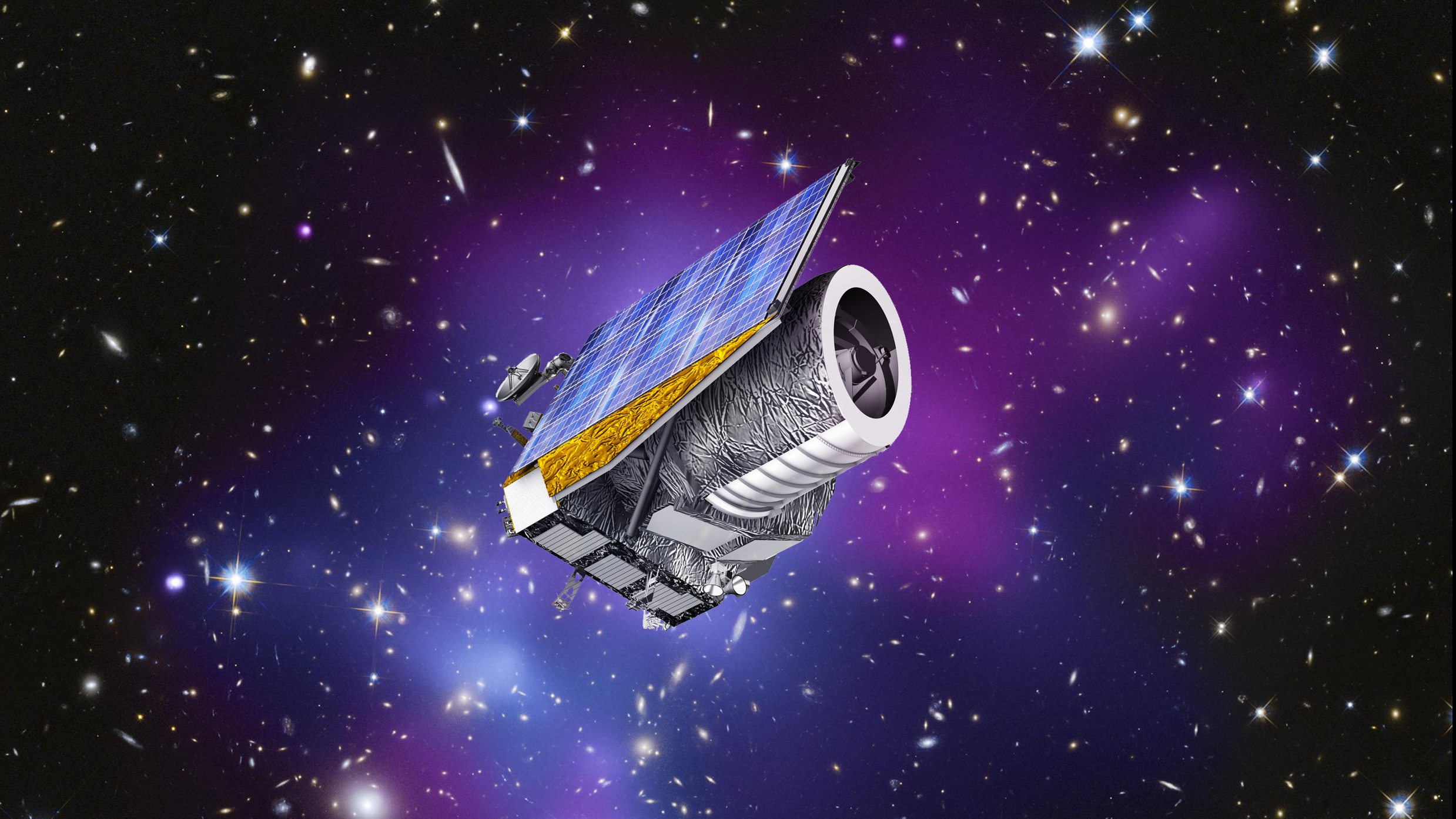

It’s not often we discover how well Philtec sensors perform for customers. The Euclid Satellite project a good example of our sensors being used with excellent results in cryogenic conditions.

for customers. The Euclid Satellite project a good example of our sensors being used with excellent results in cryogenic conditions.

A technical paper published in 2012 describes how Philtec’s high precision sensors were successfully used at 150°K to verify the distortion of lens holders to be <1 micron, well within the project requirements.

REFERENCE

‘Test Results of High-Precision Large Cryogenic Lens Holders’, 2012, Proceedings of the SPIE Publication “Modern Technologies in Space- and Ground-based Telescopes and Instrumentation II”.

The complete description of Philtec sensor installation and calibrations at cryogenic temperatures are found at ‘Section 4 Metrology’.

This work was conducted to verify the accuracy of the Euclid Space Telescope Lenses. Euclid is a space telescope currently under development by the European Space Agency and the Euclid Consortium. Launch date scheduled for 2022.

CUSTOMER FEEDBACK

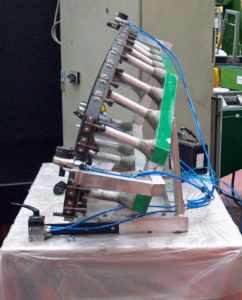

“We just got some feedback about the 9 sensors with special configuration and copper sheathing. They are quite satisfied by the sensors, which are well resisting against the 400°C. They have done several tests and measurement campaigns in laboratory and on flight.”

THE APPLICATION

Philtec has delivered 9 sensors to be used during helicopter flights to measurement displacement of engine components. The sensors have 40 mm displacement range and are designed for 400°C continuous tip exposure.

The sensors are equipped with the following options:

Option B – Connectorized Probe

Option C9 – Bendable Copper Cable Jacket, Part B

Option E2 – 3 m total fiber cable length

Option P – Polynomial Curve Fits

Option Q – Connectorized Power Supply and BNC Outputs

Option T6 – Custom 90° Tip with Threaded Probe Extension

Option T9 – 400°C High Temperature Probe Construction

Philtec builds custom displacement sensor systems to meet application requirements, which often include extreme environments. This month we delivered 8 sensors having 200 KHz bandwidth (sensor speed). The probe tips are threaded and connectorized so they may be separated from the sensor electronics.

CUSTOMER FEEDBACK

“I wanted to let you know the sensors worked as designed during our tests. I may follow up with Chris on a few specific questions as we begin to sift through all of our data. Thank you again for your professionalism and for all your support.” … Sincerely, VMR, Mechanical Engineer

THE APPLICATION

Five special right angle probes were delivered for a 1000°F tip exposure test.

Philtec is well known throughout the worldwide aerospace community. Here are some of the companies that have used Philtec’s sensors in their test and development programs. .

.

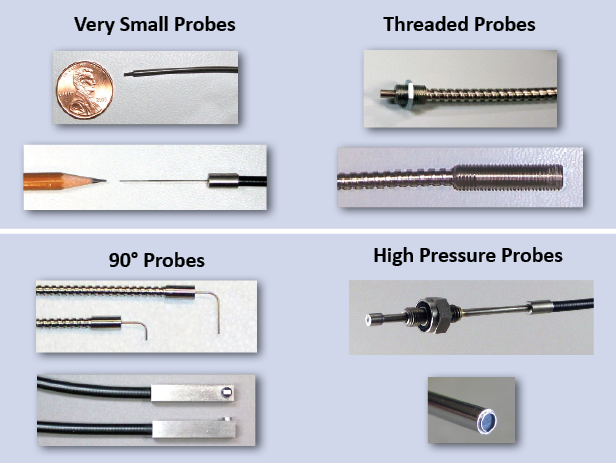

There are three options for sealing the leak path thru the fibers under pressure:

1. Epoxy filled tips

2. Sapphire Windows epoxied into tip counterbores

3. Sapphire Windows brazed into tip counterbores

The best solution for an application depends upon several factors such as: the size of the fiber bundle, the dimensions of the probe tip, as well as the amount of applied pressure. Pressure can be static, reciprocating or pulsing. Extreme temperatures can be coupled with high pressures, and the probes could be submerged in oils or cryogenic fluids. Effectiveness of the seal and cost are major considerations. Philtec engineers can assist with the choice and design of the probe.

Philtec has partnered with the Italian company Technosens to provide the complete turnkey solution for automatic production lines. The method used is to compare a production piece glass shape to the shape of a master frame as shown here.

The production line glass is placed against the master frame, and Philtec’s non-contact sensors measure distance to the glass at 50 locations. With data from 50 sensors, the shape of the glass is accurately mapped. Philtec’s non-contact optical sensors provide a scratch-free solution that is ideal for thin glass, where contact gages such as LVDTs can move and distort the glass when applied via air pressure.

With Technosens equipment, each measured piece has a complete traceability and the production is real time monitored with advanced statistics on process, moulds, system analysis (SPC, MSA) to have the maximum reduction of discarded pieces.

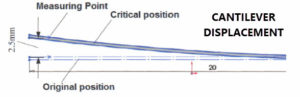

Sensor probes are to be generally mounted normal (perpendicular) to a target surface. With some applications, such as displacement of a cantilever beam, the target surface rotates as deflects. In other applications, due to installation constraints, the probe can not be mounted normal to the surface. In applications where tilt is unavoidable, what sensors can be used?

Sensor probes are to be generally mounted normal (perpendicular) to a target surface. With some applications, such as displacement of a cantilever beam, the target surface rotates as deflects. In other applications, due to installation constraints, the probe can not be mounted normal to the surface. In applications where tilt is unavoidable, what sensors can be used?

Our latest application note Sensor Applications With Tilt provides guidance on sensor performance and selection.

PHILTEC, Inc. | Annapolis, Maryland U.S.A. | tel: 410-757-4404 | fax: 410-757-8138 | e-mail: sensors@philtec.com