This short video highlights Standard and Customized Sensors. These devices are commonly inserted/installed into equipment or machinery that may present extreme conditions to the probes. Most applications require some customization of the probes and fiber optic cables. Philtec engineers optimize custom sensor designs to achieve best performance in their application.

Archive | February, 2020

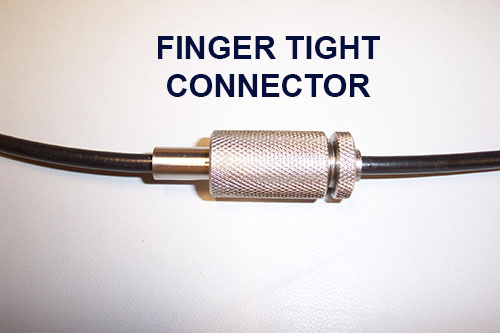

Vibration Proof Connectors

For applications where probes and fiber cables are exposed to high vibration levels, we recommend use of a wrench tight connector to make the connection vibration proof.

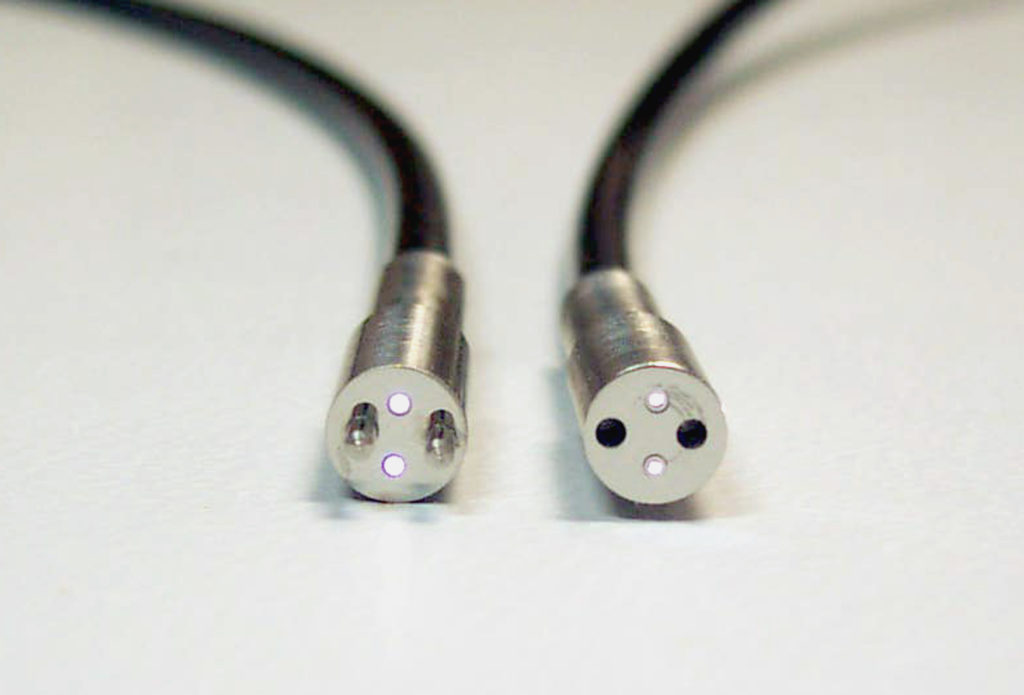

CONNECTORIZED SENSORS

Where it is desirable to be able to separate the sensor electronics from the measuring probes, fiber optic cables can be connectorized using a simple knurled finger tight design. And damaged tips can easily be replaced.

There are other reasons why the cable could be connectorized:

- Different tips such as straight or 90° of the same model can be interchanged

- Cable lengths can be extended beyond standard limitations

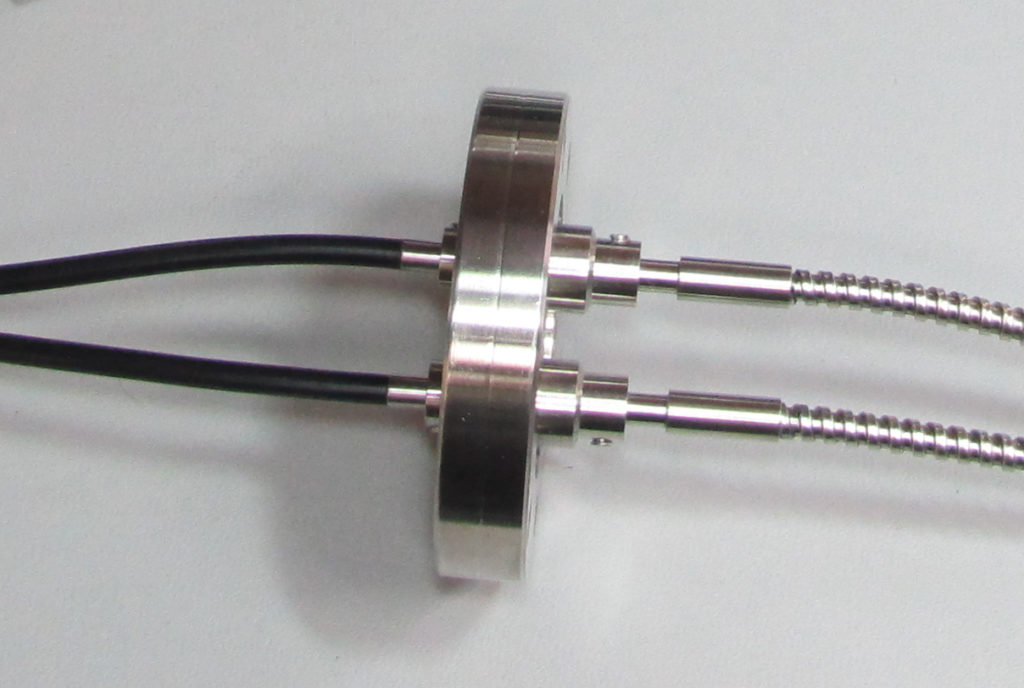

- A UHV passthru fitting can be added to the sensor system

- Different cable jacket materials can be used for vacuum and ambient sides

Long Length Fiberoptic Cables

PROBLEM

Quartz fibers have excellent transmission over long lengths, but they are very expensive and usually cost prohibitive. A recent customer asked for a model D171 sensor with 45 meter length for displacement measurements in vacuum and high magnetic field.

SOLUTION

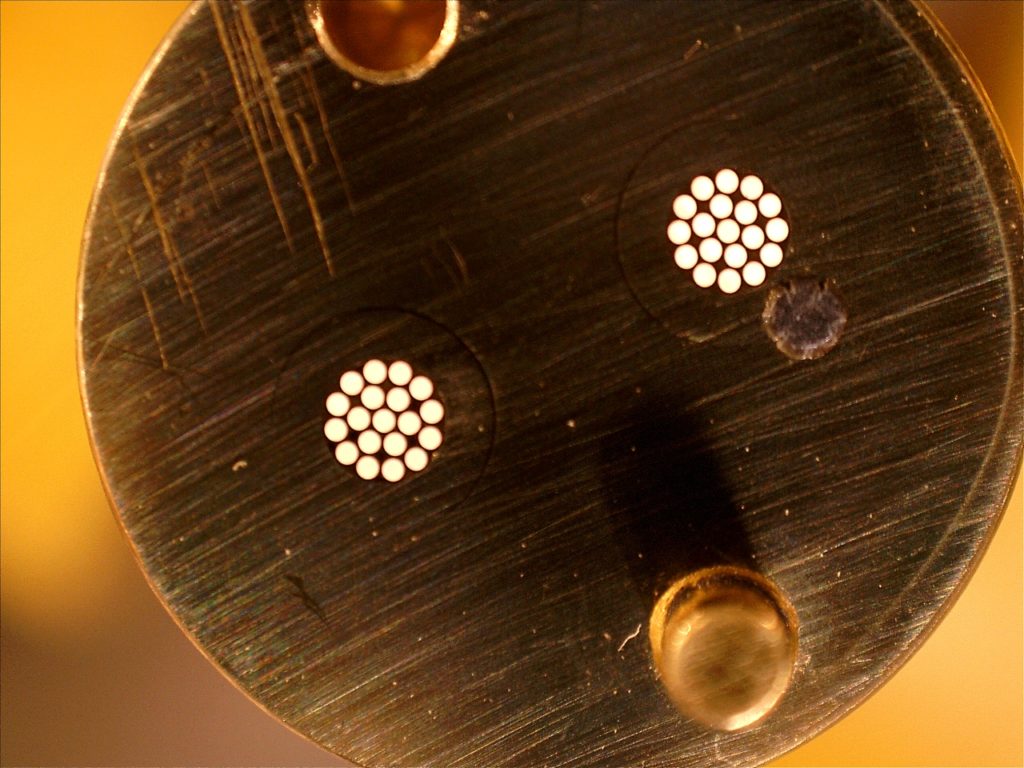

A 3-piece cost saving system was devised where only nineteen 200µm quartz fibers were used to illuminate 10% of the model D171 probe area.

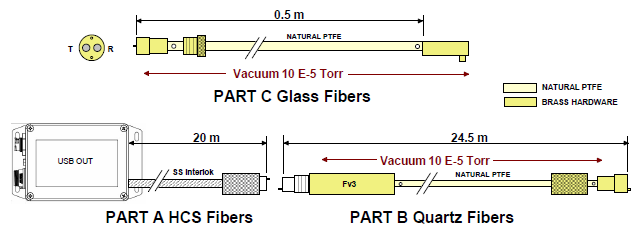

Part A – Two Ø 1000 µm Hard Clad Silica Fibers, 20 m long in air

Part B – Two Ø 1000 µm Bundles of Ø 200µm Silica/Silica (Quartz) Fibers, 24.5m long in vacuum

Part C – Ø 4320 µm D171 Glass Fibers, 0.5 m long in Vacuum

Part A has two Ø1000µm fibers at the connector interface:

Part B Ø1000 µm fiber bundles each have 19 fibers at the connector interface:

one transmits light and one returns reflected light.

Part B transmit fibers were randomly mixed with Part C glass fibers. Although Part B fibers illuminated just 10% of Part C fibers, this D171 sensor calibrated to an acceptable 70 mm displacement range. And therefore, the system cost was much lower than it would otherwise have been if all of the D171 fibers had been illuminated by quartz fibers.

Search Blog

Recent Posts

Archives

Categories

- 90° Probes

- Aerospace

- Auto Glass Shape Gaging

- connectors

- Cryogenic environments

- cryogenic turbopumps

- Displacement Sensor

- Fiber Optic Vacuum Passthru

- Fiberoptic Sensors

- FO cables

- Fretting Corrosion

- Helicopter Flight test

- High pressure environments

- High Temperature

- Hot Targets

- Liquid Hydrogen

- Liquid Nitrogen

- Liquid Oxygen

- Magnetic Fields

- Measurements in fluids

- Methane

- Miniaturized Sensors

- multiplexing sensors

- Non-Contact Sensing

- Probe Misalignment

- Quality Control

- Quartz Fibers

- Right Angle Probes

- Rotor Dynamics

- space cryogenics

- Space Launch Vehicles

- Space Telescope Lens

- Submerged in fluids

- Target Tilt

- Thread Inspection

- Tribology

- turbine blade tip clearance

- turbine speed probes

- turnkey solution

- Uncategorized

- USB Powered Sensors

- vacuum passthru

- Wireless Sensors