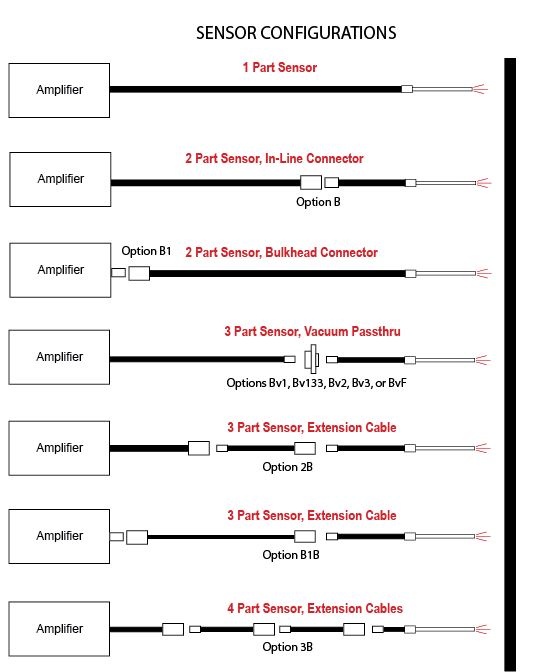

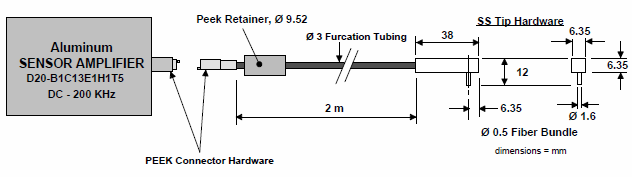

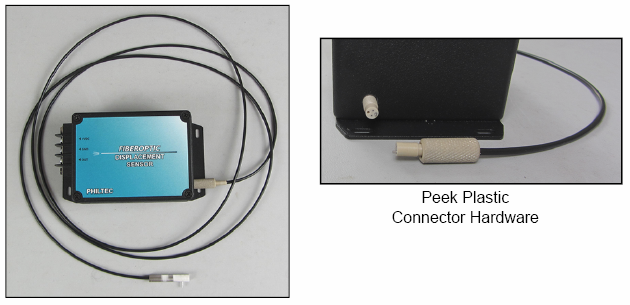

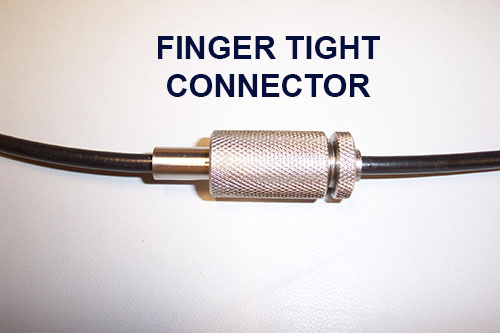

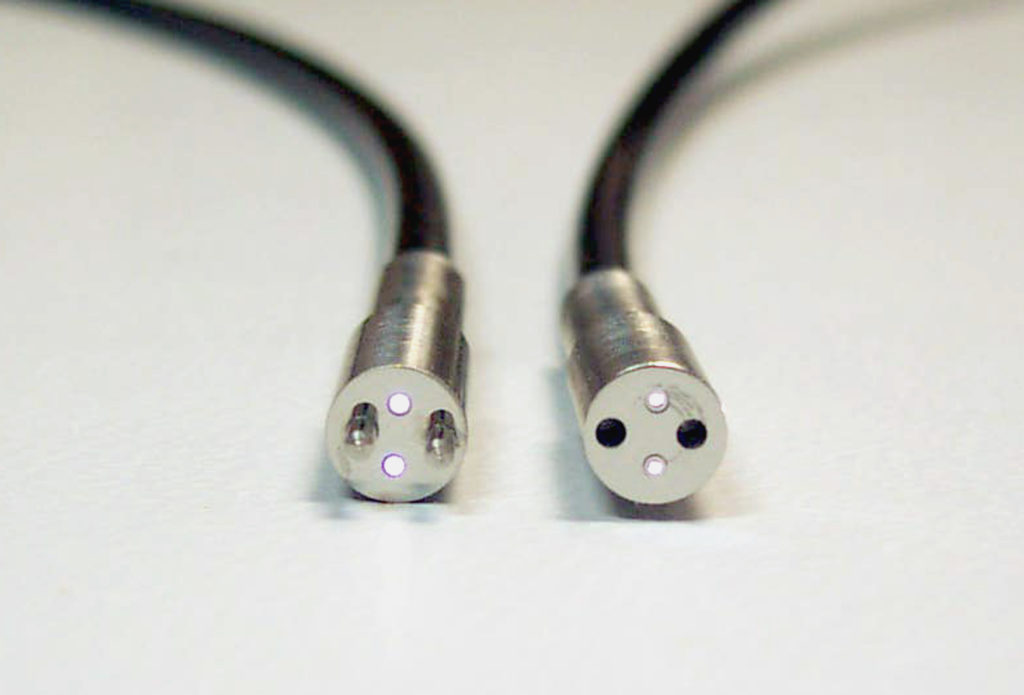

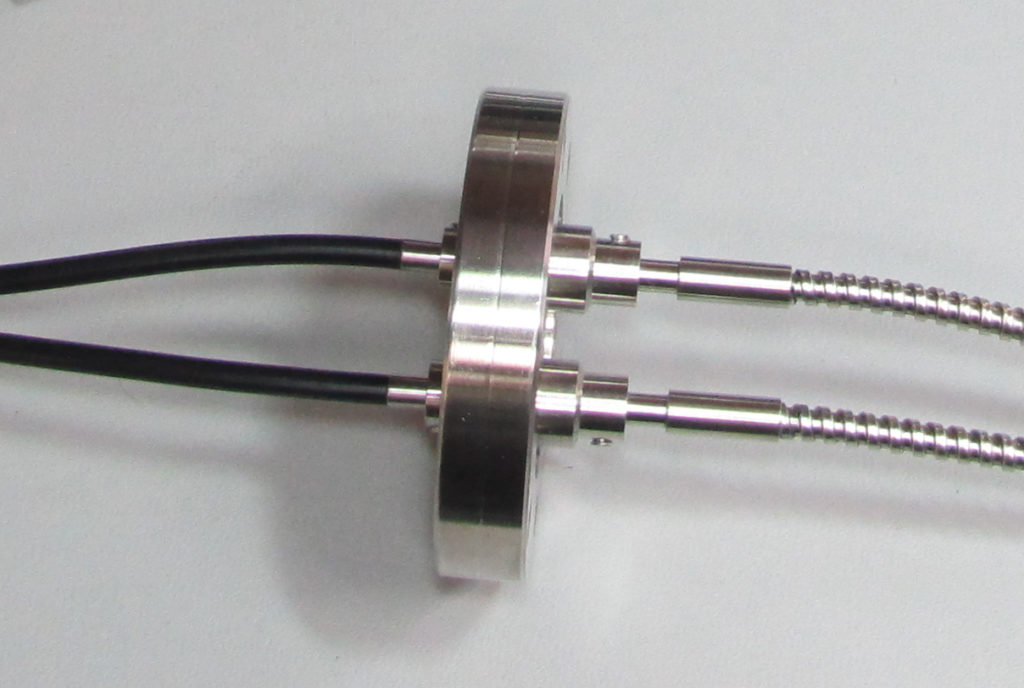

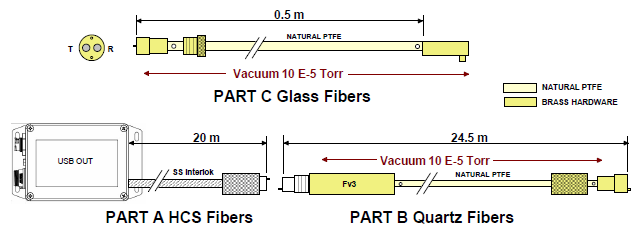

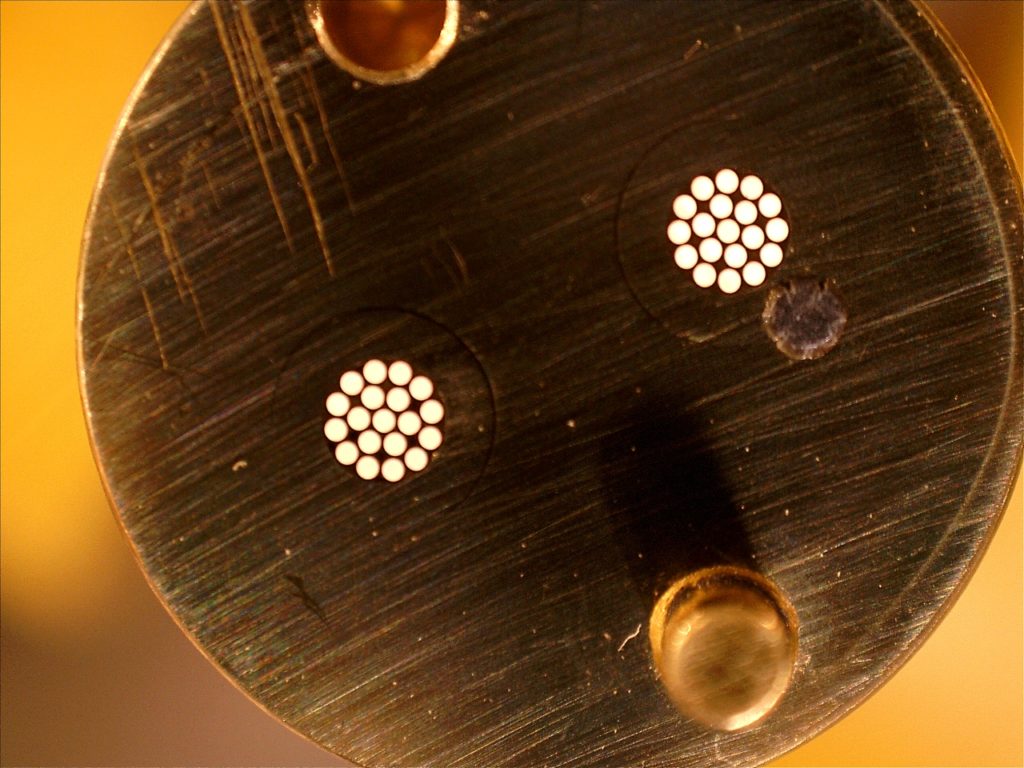

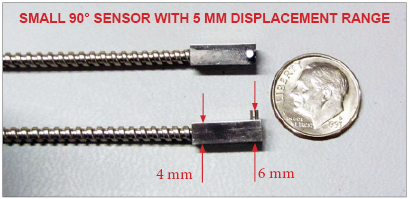

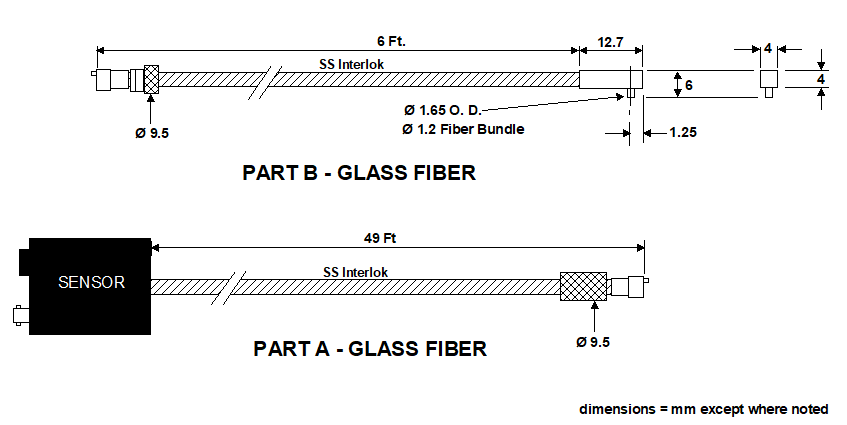

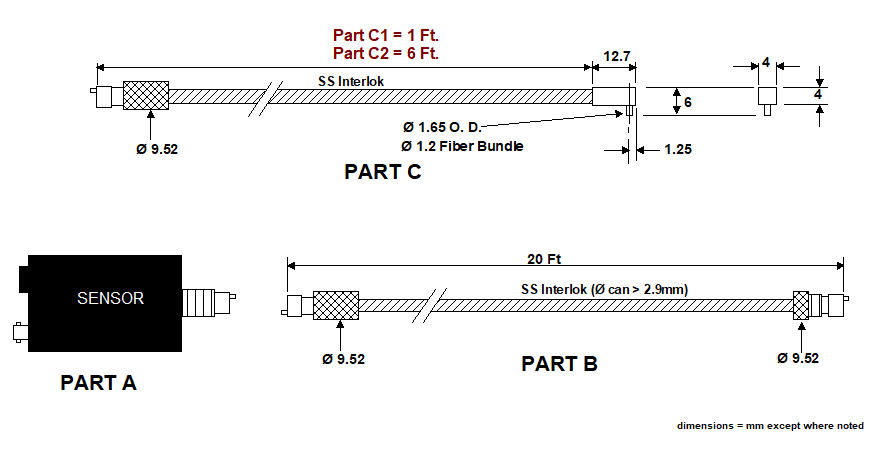

Philtec Fiber Optic sensors can make displacement measurements inside of mechanisms, machinery and vacuum chambers. To gain access to the measurement locations, Fiber Optic cables may be connectorized for the probe tips to be separated from the electronics. In some complex applications, more than one joint may be required for the installation and removal of the sensor systems. An illustration shows sensor configurations with as many as four parts that have been made and are available for some of Philtec’s sensor products. Contact our application engineering team to see if one of these systems can work for you…sales@philtec.com