This short video highlights Standard and Customized Sensors. These devices are commonly inserted/installed into equipment or machinery that may present extreme conditions to the probes. Most applications require some customization of the probes and fiber optic cables. Philtec engineers optimize custom sensor designs to achieve best performance in their application.

Archive | Uncategorized RSS feed for this section

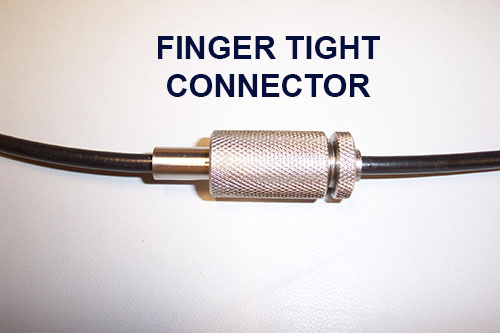

CONNECTORIZED SENSORS

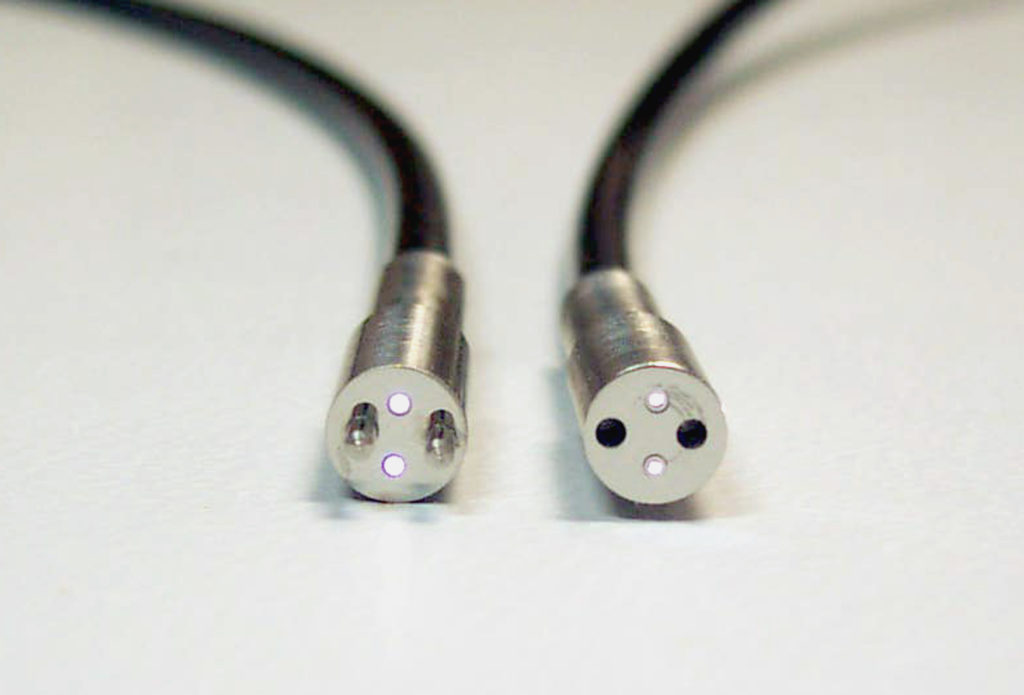

Where it is desirable to be able to separate the sensor electronics from the measuring probes, fiber optic cables can be connectorized using a simple knurled finger tight design. And damaged tips can easily be replaced.

There are other reasons why the cable could be connectorized:

- Different tips such as straight or 90° of the same model can be interchanged

- Cable lengths can be extended beyond standard limitations

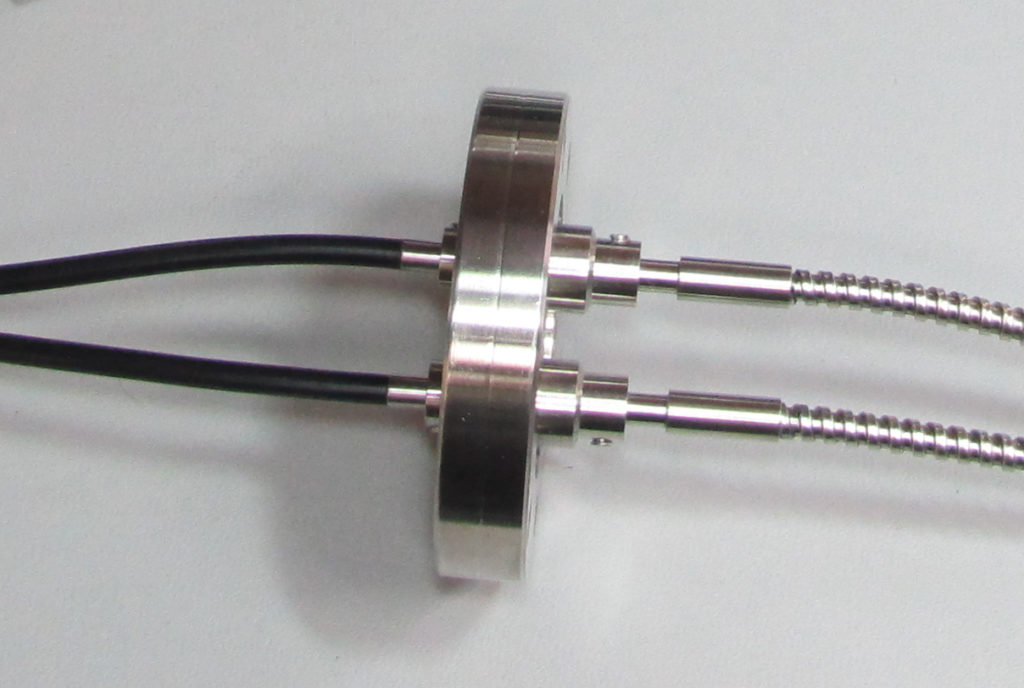

- A UHV passthru fitting can be added to the sensor system

- Different cable jacket materials can be used for vacuum and ambient sides

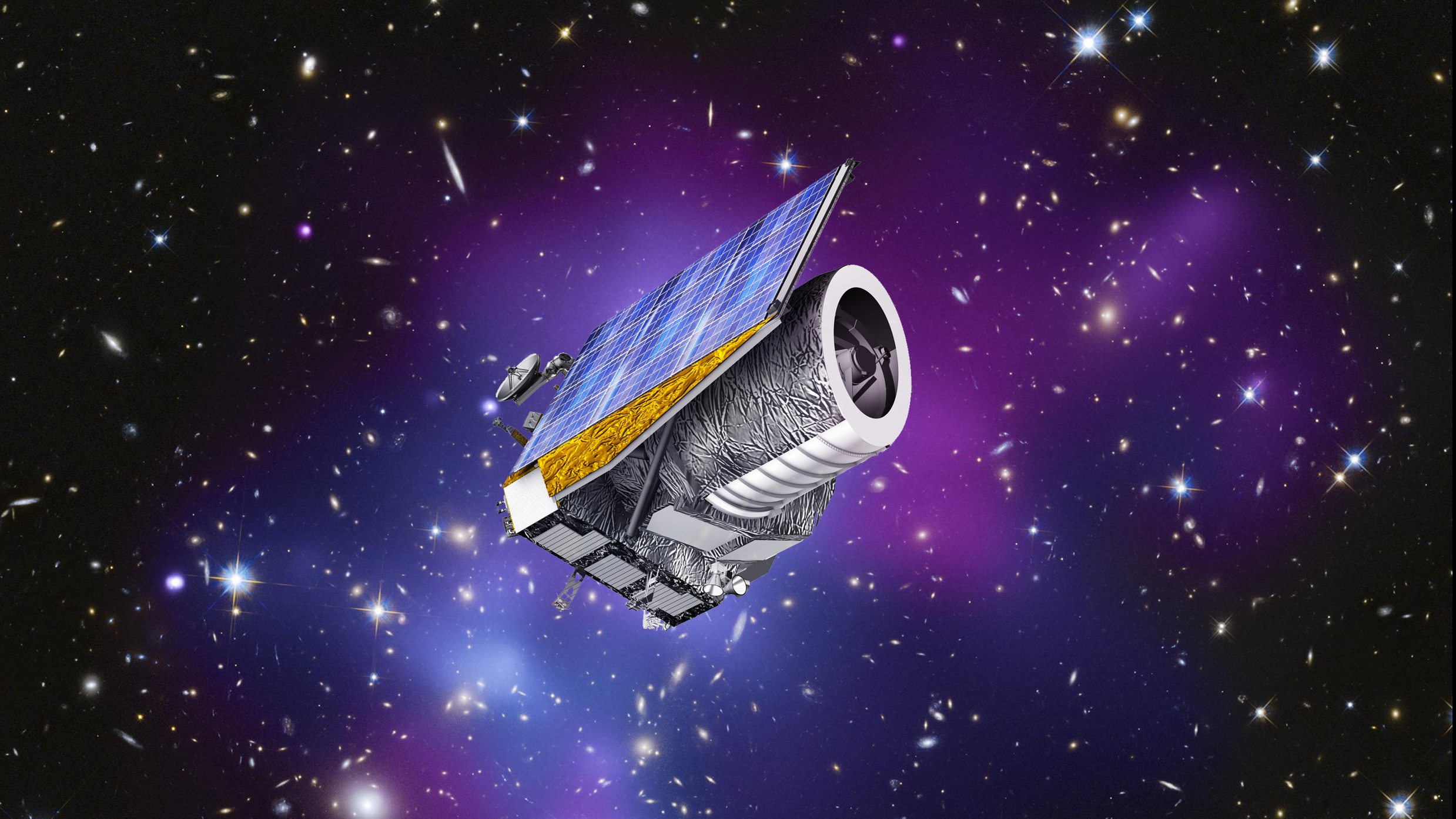

Space Telescope Lens Tests

It’s not often we discover how well Philtec sensors perform for customers. The Euclid Satellite project a good example of our sensors being used with excellent results in cryogenic conditions.

for customers. The Euclid Satellite project a good example of our sensors being used with excellent results in cryogenic conditions.

A technical paper published in 2012 describes how Philtec’s high precision sensors were successfully used at 150°K to verify the distortion of lens holders to be <1 micron, well within the project requirements.

REFERENCE

‘Test Results of High-Precision Large Cryogenic Lens Holders’, 2012, Proceedings of the SPIE Publication “Modern Technologies in Space- and Ground-based Telescopes and Instrumentation II”.

The complete description of Philtec sensor installation and calibrations at cryogenic temperatures are found at ‘Section 4 Metrology’.

This work was conducted to verify the accuracy of the Euclid Space Telescope Lenses. Euclid is a space telescope currently under development by the European Space Agency and the Euclid Consortium. Launch date scheduled for 2022.

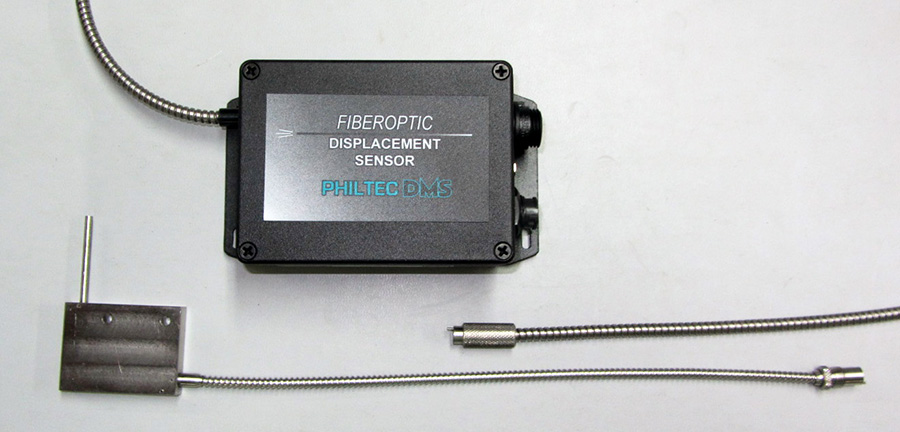

Probes for Cryogenic Turbo Pumps

Philtec builds custom displacement sensor systems to meet application requirements, which often include extreme environments. This month we delivered 8 sensors having 200 KHz bandwidth (sensor speed). The probe tips are threaded and connectorized so they may be separated from the sensor electronics.

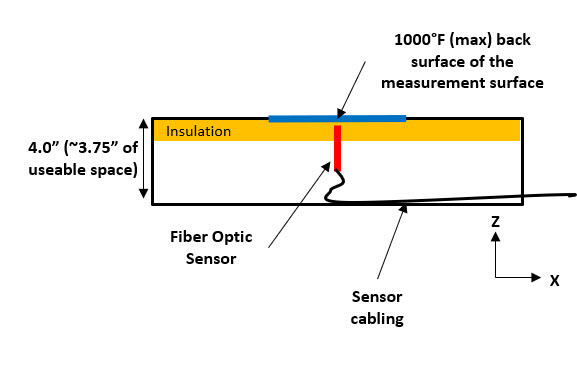

1000°F Application

CUSTOMER FEEDBACK

“I wanted to let you know the sensors worked as designed during our tests. I may follow up with Chris on a few specific questions as we begin to sift through all of our data. Thank you again for your professionalism and for all your support.” … Sincerely, VMR, Mechanical Engineer

THE APPLICATION

Five special right angle probes were delivered for a 1000°F tip exposure test.

Welcome to the Philtec Blog

Happy New Year, and welcome to the Philtec blog. We will be posting information and adding content on a regular basis.

Search Blog

Recent Posts

Archives

Categories

- 90° Probes

- Aerospace

- Auto Glass Shape Gaging

- connectors

- Cryogenic environments

- cryogenic turbopumps

- Displacement Sensor

- Fiber Optic Vacuum Passthru

- Fiberoptic Sensors

- FO cables

- Fretting Corrosion

- Helicopter Flight test

- High pressure environments

- High Temperature

- Hot Targets

- Liquid Oxygen

- Magnetic Fields

- Measurements in fluids

- Miniaturized Sensors

- multiplexing sensors

- Non-Contact Sensing

- Probe Misalignment

- Quality Control

- Quartz Fibers

- Right Angle Probes

- space cryogenics

- Space Launch Vehicles

- Space Telescope Lens

- Target Tilt

- Thread Inspection

- Tribology

- turbine blade tip clearance

- turbine speed probes

- turnkey solution

- Uncategorized

- USB Powered Sensors

- vacuum passthru

- Wireless Sensors