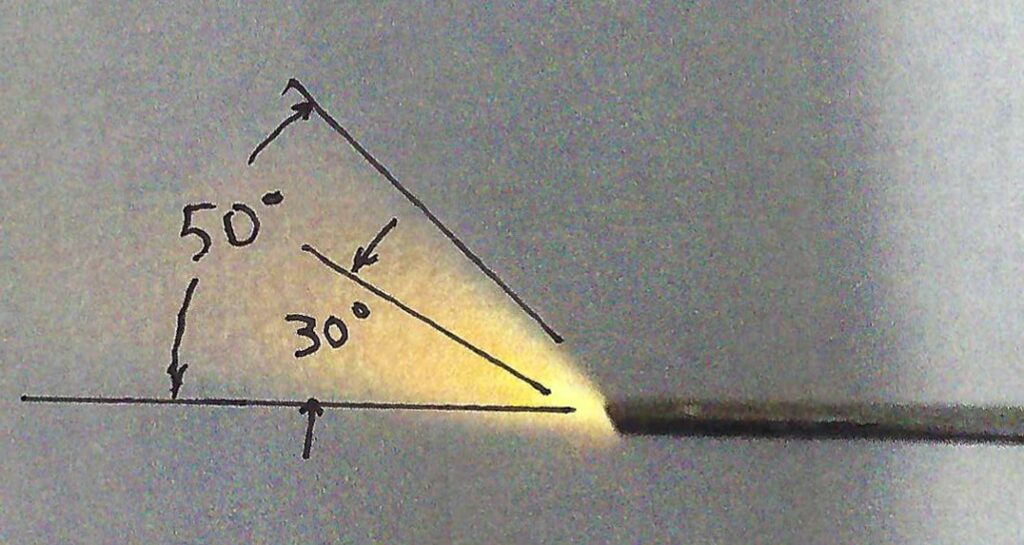

The previous App Note ‘Bending Light’ showed that the light beam emitted from a fiber optic probe can be redirected to a different emission angle by polishing the fibers at an angle to the probe axis.

A new customer wants to measure turbine speed by sensing the passage of 1 mm thick blades.

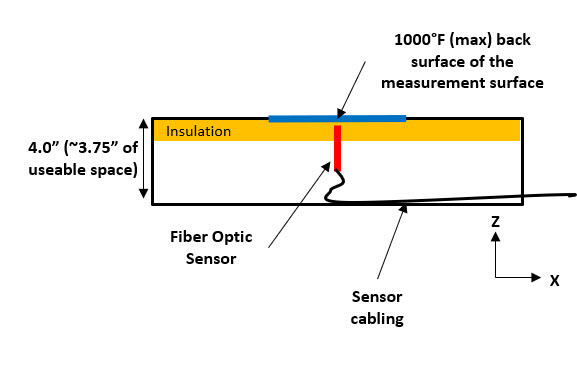

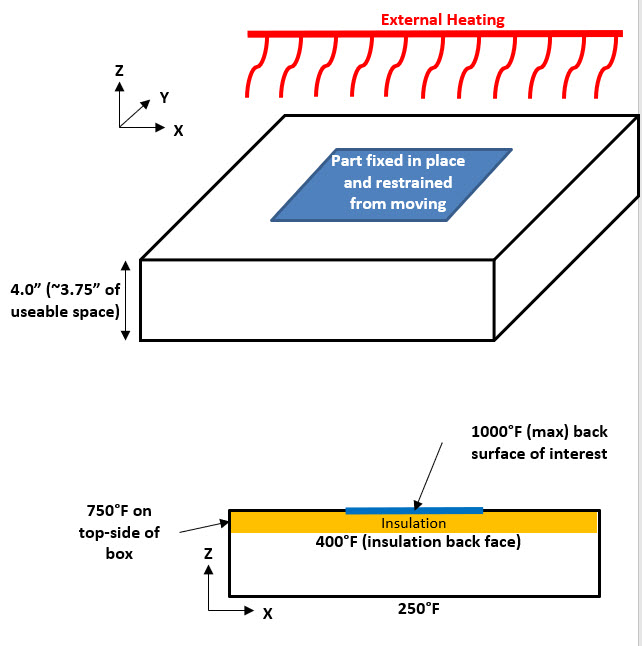

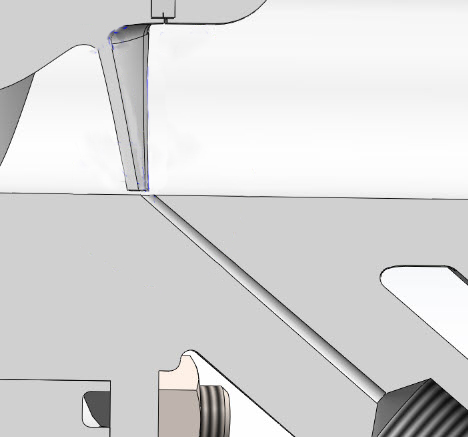

THE PROBLEM: Access to the blades can only be made at a 50° angle to the blade tip surface. And, we’re not sure if the blade can be sensed at that angle

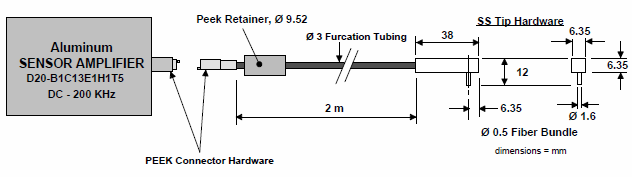

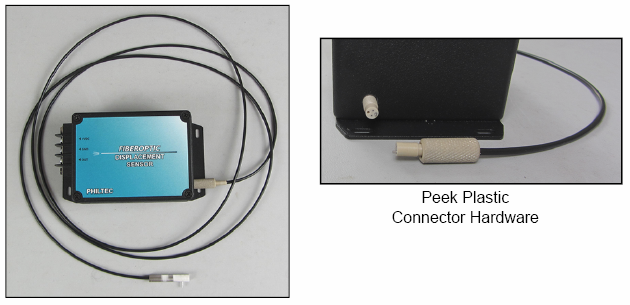

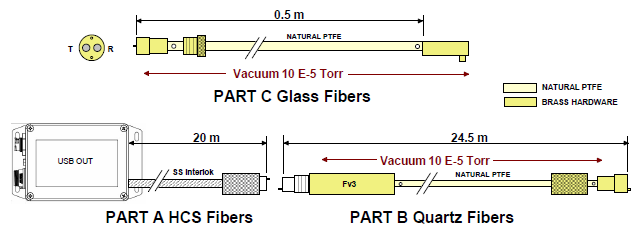

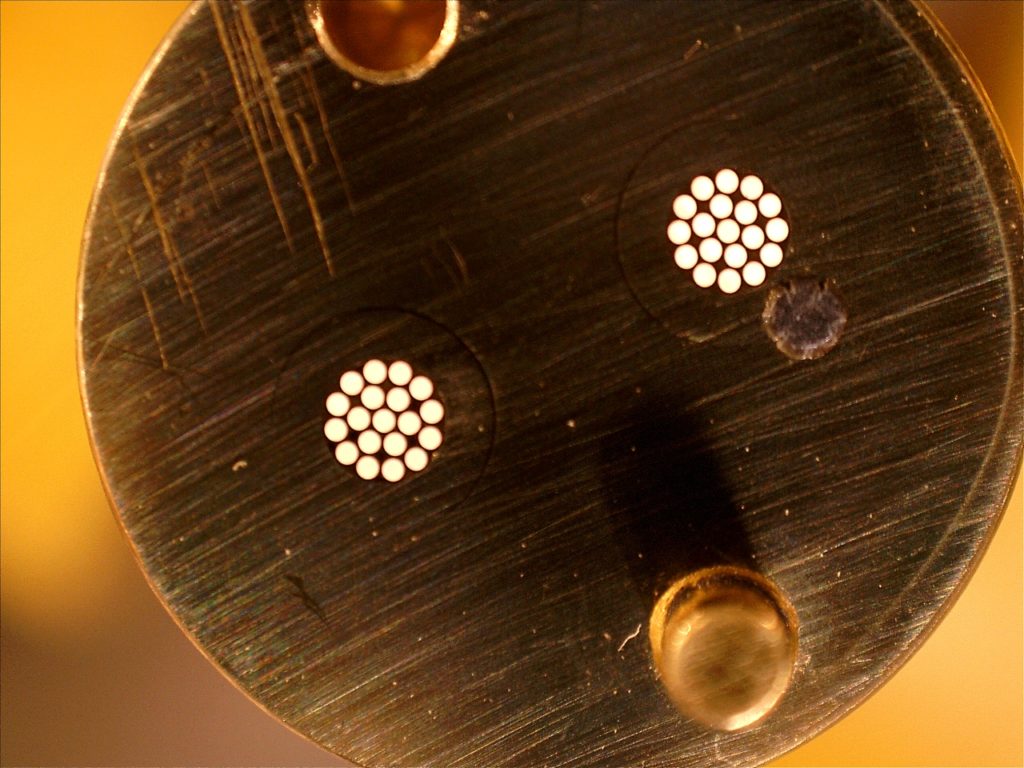

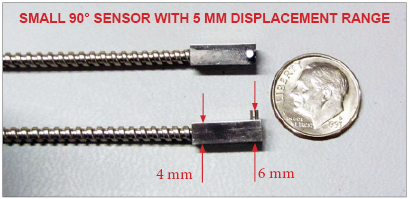

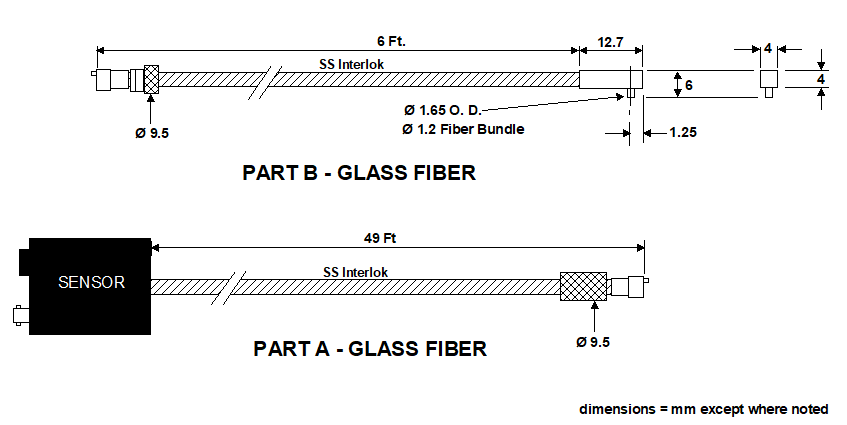

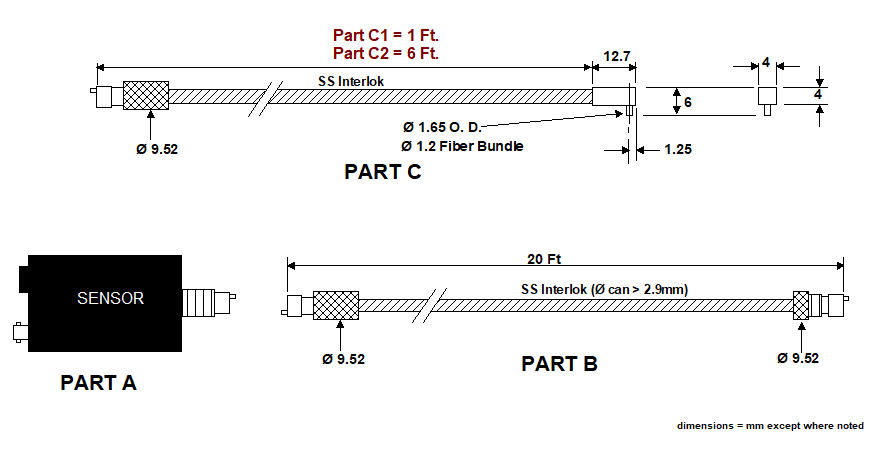

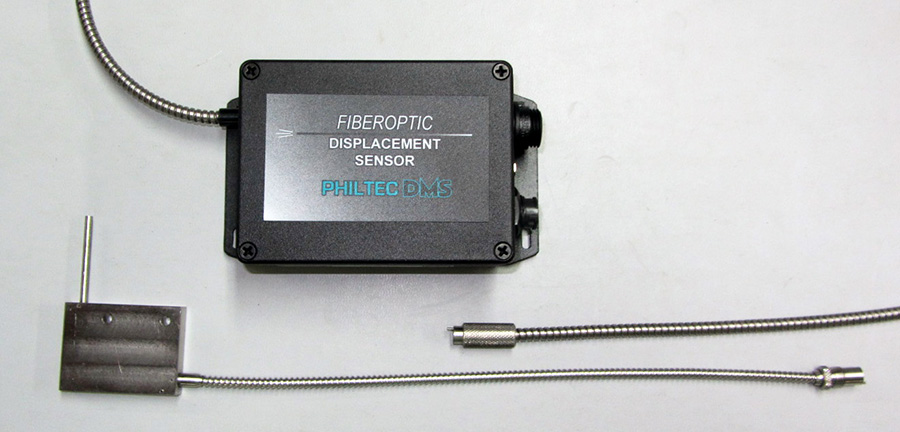

TEST PROBE

A 1.5 mm diameter test probe was made with the fibers polished to a 30° angle. When the fibers were illuminated, the emitted light beam filled a 50° cone.

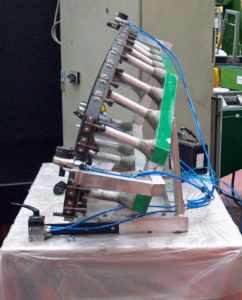

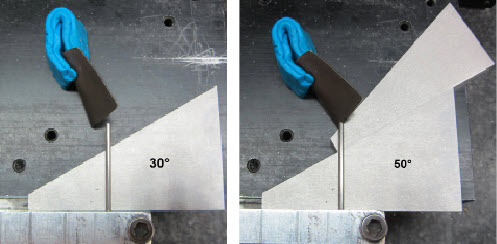

TEST SETUP

A 1 mm blade was placed on a linear stage and mounted at 30° and 50° angles to the test probe.

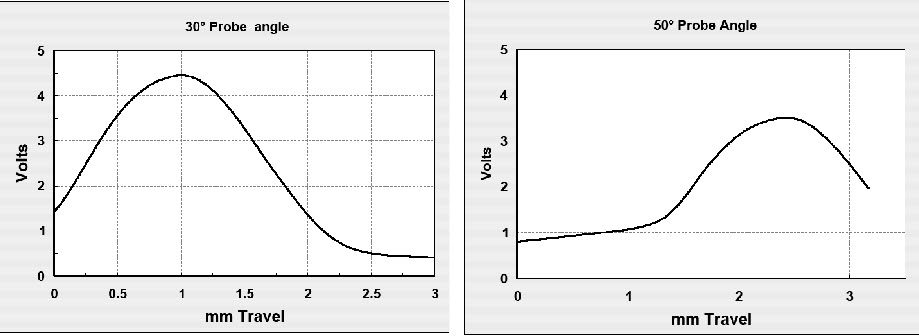

The probe output was recorded as the blade moved past the light beam of the probe.

RESULTS

30° Angle : Max/Min = 9 ….. 50° Angle : Max/Min = 4.4

CONCLUSION

Angle polished probes can detect turbine blade passage up to a 50° access angle.