Send us a sketch or drawing of your application requirements. We’ll make a sensor configuration drawing for your review. Email sensors@philtec.com

Send us a sketch or drawing of your application requirements. We’ll make a sensor configuration drawing for your review. Email sensors@philtec.com

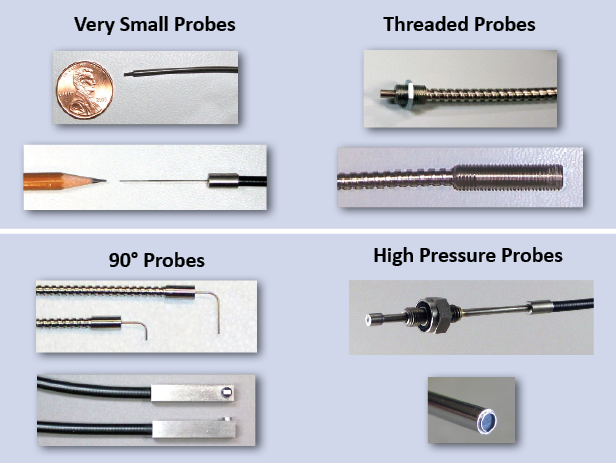

Philtec builds custom displacement sensor systems to meet application requirements, which often include extreme environments. This month we delivered 8 sensors having 200 KHz bandwidth (sensor speed). The probe tips are threaded and connectorized so they may be separated from the sensor electronics.

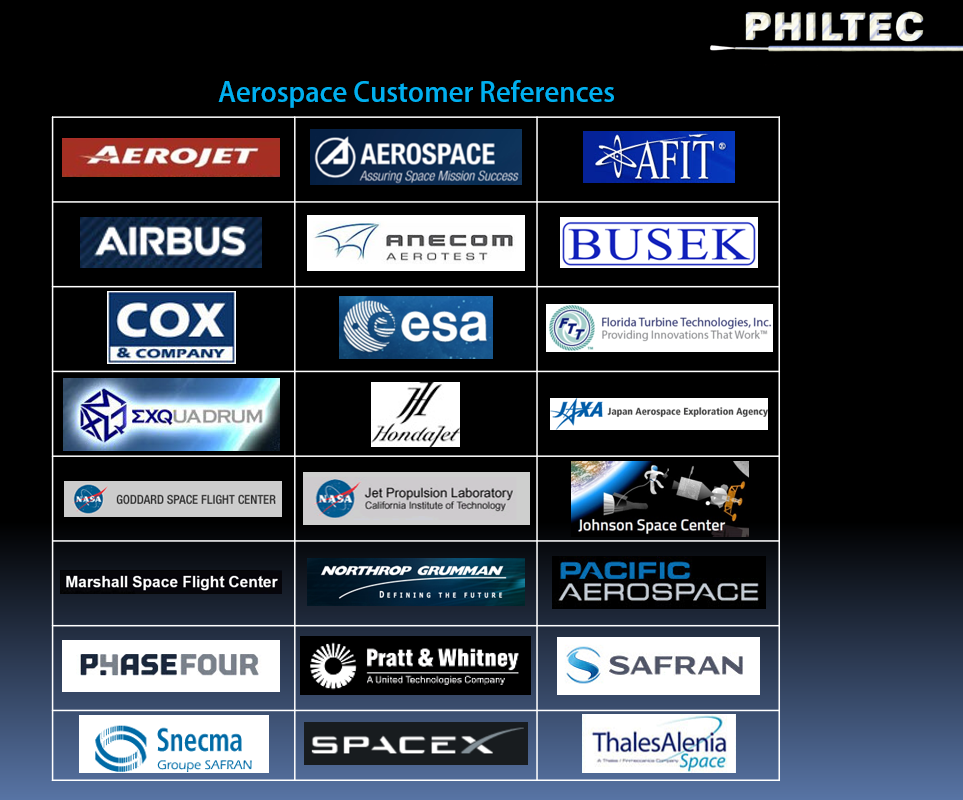

Philtec is well known throughout the worldwide aerospace community. Here are some of the companies that have used Philtec’s sensors in their test and development programs. .

.

There are three options for sealing the leak path thru the fibers under pressure:

1. Epoxy filled tips

2. Sapphire Windows epoxied into tip counterbores

3. Sapphire Windows brazed into tip counterbores

The best solution for an application depends upon several factors such as: the size of the fiber bundle, the dimensions of the probe tip, as well as the amount of applied pressure. Pressure can be static, reciprocating or pulsing. Extreme temperatures can be coupled with high pressures, and the probes could be submerged in oils or cryogenic fluids. Effectiveness of the seal and cost are major considerations. Philtec engineers can assist with the choice and design of the probe.

PHILTEC, Inc. | Annapolis, Maryland U.S.A. | tel: 410-757-4404 | fax: 410-757-8138 | e-mail: sensors@philtec.com