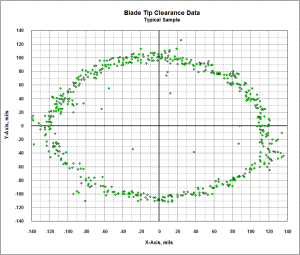

Gas and steam turbine manufacturers of fossil power plants have long used hand-held feeler gages to measure turbine blade tip clearances and inspect the roundness of the TBC linings at access ports provided for that purpose. With new construction and at overhaul, turbine blade tip-to-casing clearances at room temperature must be properly set.

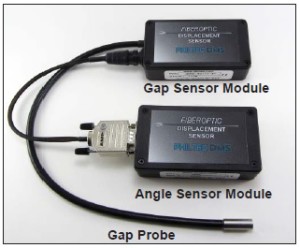

Philtec has developed the wireless non-contact sensor system CMS3400 to replace manual feeler gage methods. As a technician slowly jogs a rotor thru 360° of rotation, Gap and Angle data pairs are simultaneously recorded from 4 rows of blades and saved to a USB flash drive for offloading and data analysis. CMS3400 is a four channel wireless sensor system that digitally captures the full 360° picture of blade tip-to-casing roundness and clearance data. This product represents a major advancement in the state-of-the-art.

MORE INFO AT Wireless Sensors for Blade Tip Clearance